BRITEPLAST 100

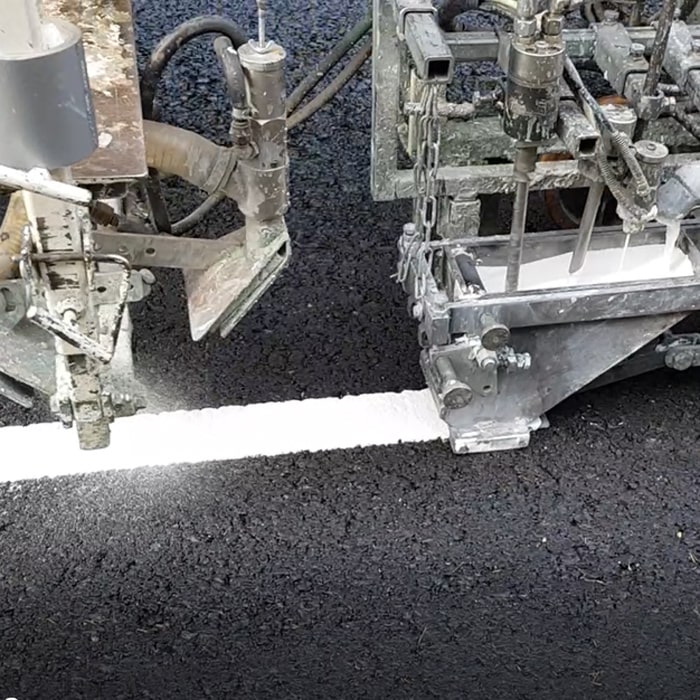

Suited to the most challenging environments, BritePlast 100 is a premium, highly durable cold plastic. Due to its ultra-bright pigments and complex binder system, BritePlast 100 is an effective solution for roads that require high visibility during the day and high reflectivity at night. Superior durability under heavy traffic loads and snowploughs with exceptional adhesion to concrete and asphalt surfaces.

Available in extrusion, screed and spray grades.

Material characteristics

(Minor variance according to application method – see product sheet for more detail)

Application temperature: 8-40°C

Drying time: 10-30 minutes (approx.)

DOWNLOAD MMA BROCHURE

BRITEPLAST PLUS

Designed to meet the highest quality standards in the world. BritePlast Plus offers superior performance in both dry and wet conditions. A highly durable, sustainable road marking that stands up to harsh weather conditions and the demands of today’s busy roads. BritePlast Plus is specifically designed to provide a high definition road marking with exceptional reflectivity, luminance and anti-skid resistance properties.

Available in extrusion, screed and spray grades.

Material characteristics

(Minor variance according to application method – see product sheet for more detail)

Application temperature: 8-40°C

Drying time: 10-30 minutes (approx.)

DOWNLOAD MMA BROCHURE

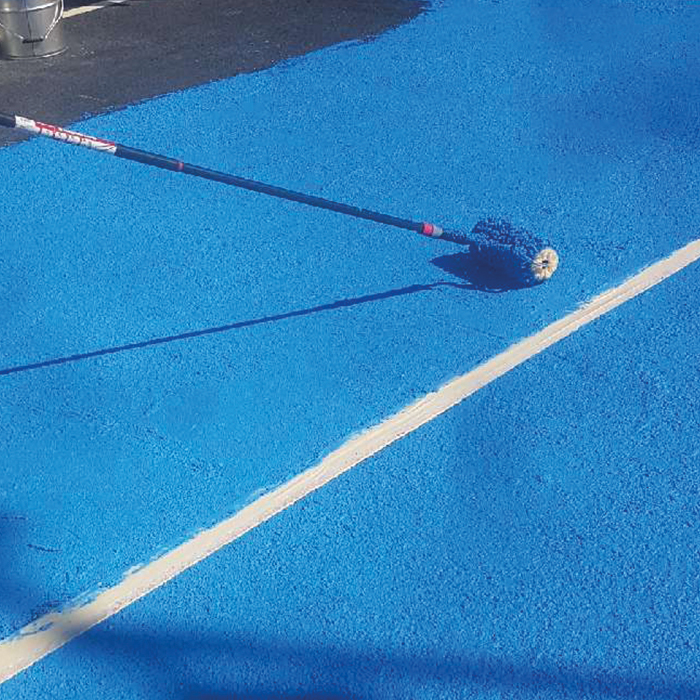

BRITEPLAST GRIP

Formulated to display all the outstanding features of our BritePlast technology, BritePlast Grip offers exceptional anti-skid properties. BritePlast Grip comes in a range of colours and is specifically suited to bus and cycle lanes, walkways, car bays and traffic calming strips. A quick-drying solution, BritePlast Grip ensures minimum disruption to pedestrian or motor traffic and is available in a number of grades for a truly versatile product.

Available in extrusion and screed grades.

*The BritePlast portfolio is available in a variety of traffic colours and in a 98:2 system or 1:1 system.

Applications

Apply by spray, extrusion, shoe or by agglomerate. MMA can also be hand-applied by screed box (drag shoe), roller or trowel. Flat line is normally mixed with a static mixer.

Material characteristics

(Minor variance according to application method – see product sheet for more detail)

Application temperature: 8-40°C

Drying time: 10-30 minutes (approx.)

DOWNLOAD MMA BROCHURE

STEPFLEX

StepFlex thermoplastic can also be constructed for cold plastic. Thixotropic materials already exist.

Whilst offering outstanding performance on wet-night visibility, StepFlex has been specifically designed to withstand the heavy mechanical erosion that occurs during winter maintenance periods. The step like structure is applied diagonally towards the snowplough angle making for a stronger structure and therefore minimising any erosion through this busy maintenance period. StepFlex is the best winter performing Agglomerate that Kelly Bros have employed to date.

Material characteristics

(Minor variance according to application method – see product sheet for more detail)

Application temperature: 8-40°C

Drying time: 10-30 minutes (approx.)

DOWNLOAD MMA BROCHURE